Chrysalis- Work in Progress, Corning Inc. Research residency

In the summer of 2016 I started the Specialty Glass Residency in upstate New York. The Specialty Glass Residency is a joint program of The Corning Museum of Glass and Corning Incorporated that supports artists in exploring the use of specialty glass materials to inform their body of work.

One of the materials I was introduced to at Corning was a glass ceramic of the Rhino glass product family developed by Corning Inc. The Rhino glass ceramics consist of different compositions, each formulated for different purposed such as bullet proof vest shields, ceramic teeth filling, countertops and pressed table ware. The basic characteristics of the glass ceramic is its working properties. You batch the raw materials and melt them in a furnace from where you can extract it for your usage. It works best if you can shape a product in one heat. If the glass ceramic ( clear when initially heated) cools below a certain temperature range, is heated up again, via a flame or oven, it will start forming crystals in the heat. These crystals are visible at the beginning as small seed crystals that will continue transforming the glass into a ceramic as you work.

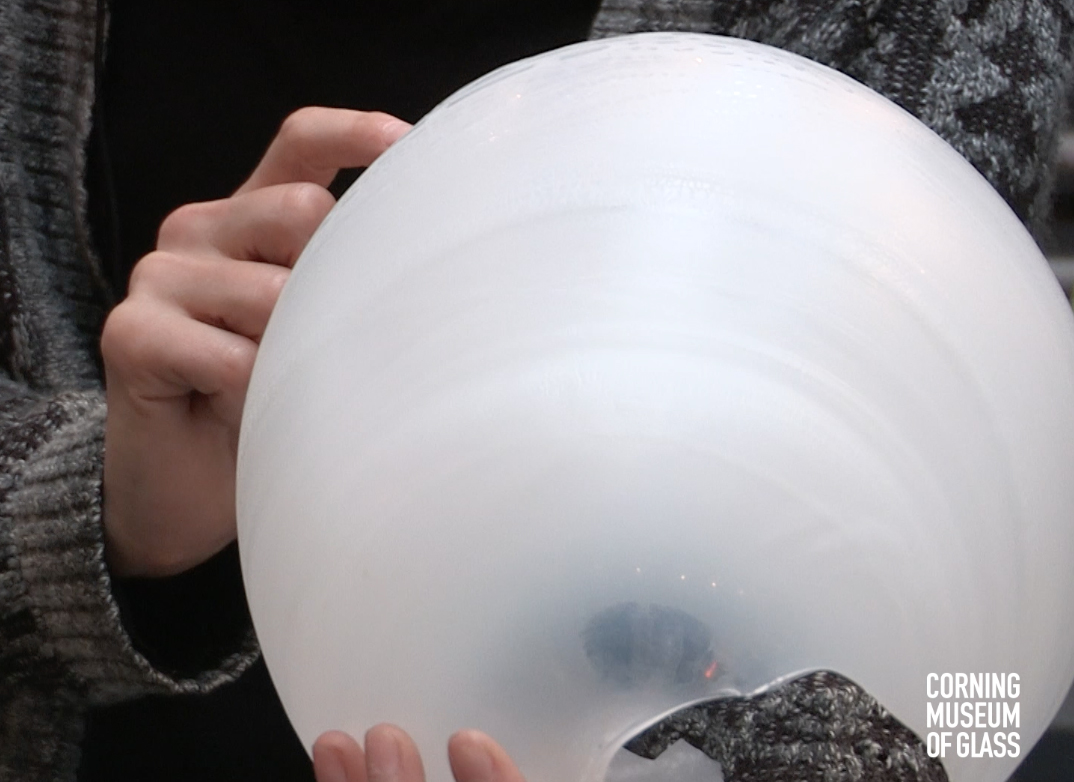

Seed crystals visible in a blown form. These seed crystals formed by gathering multiple times glass over the previously cooled start.

One blown form before reheating it and after it has been transformed into the ceramic after heating it.

The challenges with this material is, that you can not work it easily in the hot shop and blow it into forms, because as you need to constantly reheat the material to keep it soft and workable and to not make it crack as it can cool too fast. Another problem you face is that glass heats unevenly. Where it is hotter it transforms fast. This leads to having part of your form being glass and the other ceramic. Even though both materials are originating from the same source, the properties are so different that one incompatible with the other. That leads to the piece breaking, unless you either transform it fully or not transform it at all. Typically this material is used for press molding or sheet forming. To take this glass into the hot shop was very challenging. Glass is a soft skin, that can be inflated by gently blowing air into it through the blow pipe. Once the glass on your pipe turns into ceramic, it become rock hard and can't be inflated.

When working with it I was captured by the crystal formation in the clear material. The slow whitening and changing of a material body into a different one was captivating.

Streaks and textures as well as a milky translucent color are the visual striking properties of Rhino when blown.

I learned that Rhino glass was extremely shock resistant and strong. Looking at the first bubbles we blew, I was reminded of a chrysalis and thinking about the possibility of this material to be able to support my weight I wanted to make a form that was large enough for me to get inside of.

So the team of the Corning Museum of Glass and I set out to blow a form, large enough for me to be in.

In the hot shop at the Museum

After some trying we figured out the process pretty well. Watch a short video Corning produced during the initial phase here:

The still glassy bubbles, with seed crystals for the ceramic transformation embedded, had to be placed back into a kiln to bring them back up to the temperature they needed to turn into the ceramic. In order to do that they needed to be supported from the inside as they would otherwise collapse. When we started the project we didnt know about the issue of having to support them during the firing. Corning ordered loose fiber frax to stuff the bubble with for us.... Unfortunately the material arrive first months later at the end of the residency.

Unsure if we could do the second, required step of this process, we decided to shift production course as the months went by without the material arriving.

In the second phase we tested different modes to generate a chrysalis form. ranging from making it from round, fitting sections, to constructing it out of parts.

Tests for construction from Parts and shards

Jeff Mack with a blown form for round sections. Dr. Jane Cook, Chief Scientist at the Museum in the background

A full scale chrysalis model in my studio, to better understand the look and workings of it.

Drawings of various Chrysalis forms for reference.

The idea was to cut the top and bottom off and either cut them in half lengthwise or slump them into flat sheets. Which would get formed in the kiln over a cell core slump mold.

Model molds carved from Cellcore, Diesel engine filter supplied by Corning Inc.

half of a Cellcore mold in the kiln for a slump test simulating the larger bottle shaped forms blown at the. Corning Museum of Glass.

While working with the glass ceramic we didn’t know if we would be able to process large pieces of Rhino glass, as it transitions so rapidly between the soft state of glass and the crystalline state of ceramic. To create the crystalline state the glass had to be heated so much that it would slump, so it became necessary to think of ways to support the large forms in the ceram-firing so they wouldn’t collapse while transitioning. We ordered lose fiberglass stuffing but it didn’t arrive in time for the residency to be over. On the last few days we discovered that we could have made large blown forms and ceram them successfully, but midway through we changed course after a few failed attempts of ceraming unsupported blown vessel forms.

Image left: Rhino Glass bubble before ceram firing

Image Second Left: The same large Bubble after cream-firing, supported with lose fiber fill

Image Second Right: Back side of the large bubble with visible stuffing

Image Right: collapsed cream-fired large bottle shaped form, fired without support

In the end we settled on blowing small, one gather lollipop shapes, that can be combined into a large surface, like scales.

The pace of the residency is so fast, with decisions having to be made months in advance. This added a layer of difficulty in the creative process. Because of that, only at the termination of the residency I had time to really consider the raw material I had made during the residency.

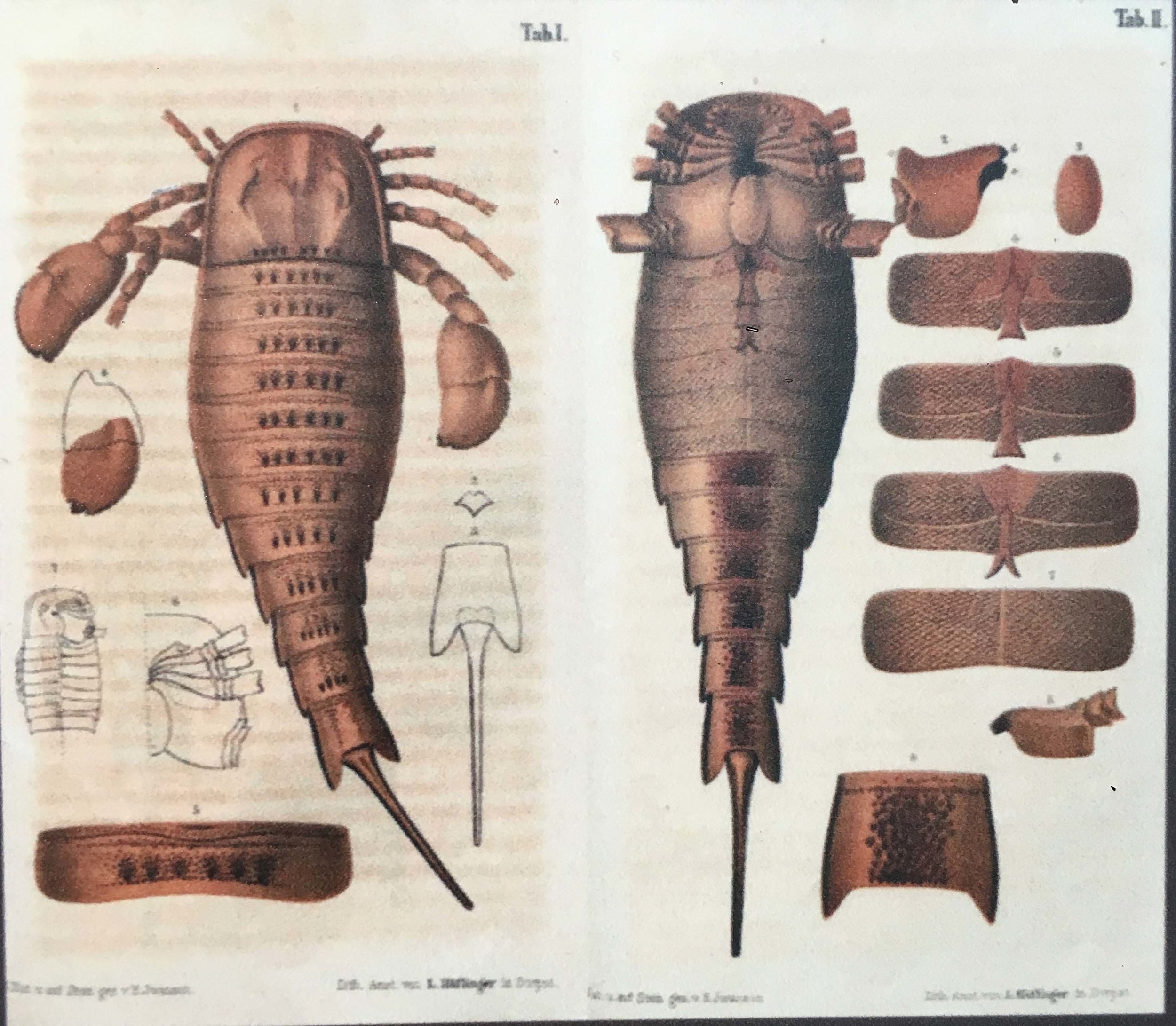

In the beginning of 2017 I had moved away from making a chrysalis that resembled that of an animal

I went back and looked at the research material I had gathered in the area. The Chrysalis had its origin in a fossile I discovered when visiting the Paleontological research Institute outside Ithaca NY. The Eurypterid is the NY state fossil, because of its abundance in the local shale bedrock. It had served me as a reference throughout the process and received some renewed attention in addition to the corsets I had seen at the Wesleyan Chapel Women’s Rights National historical Park Museum in Seneca Falls, where the first Women’s rights convention was held in 1848. There is a stunning resemblance between the exoskeleton and the corsets which led to the new phase of the project.

Eurypterid panel from the Paleontological Research Institute, Ithaca

Corset at the Wesleyan Chapel Women’s Rights National historical Park Museum in Seneca Falls

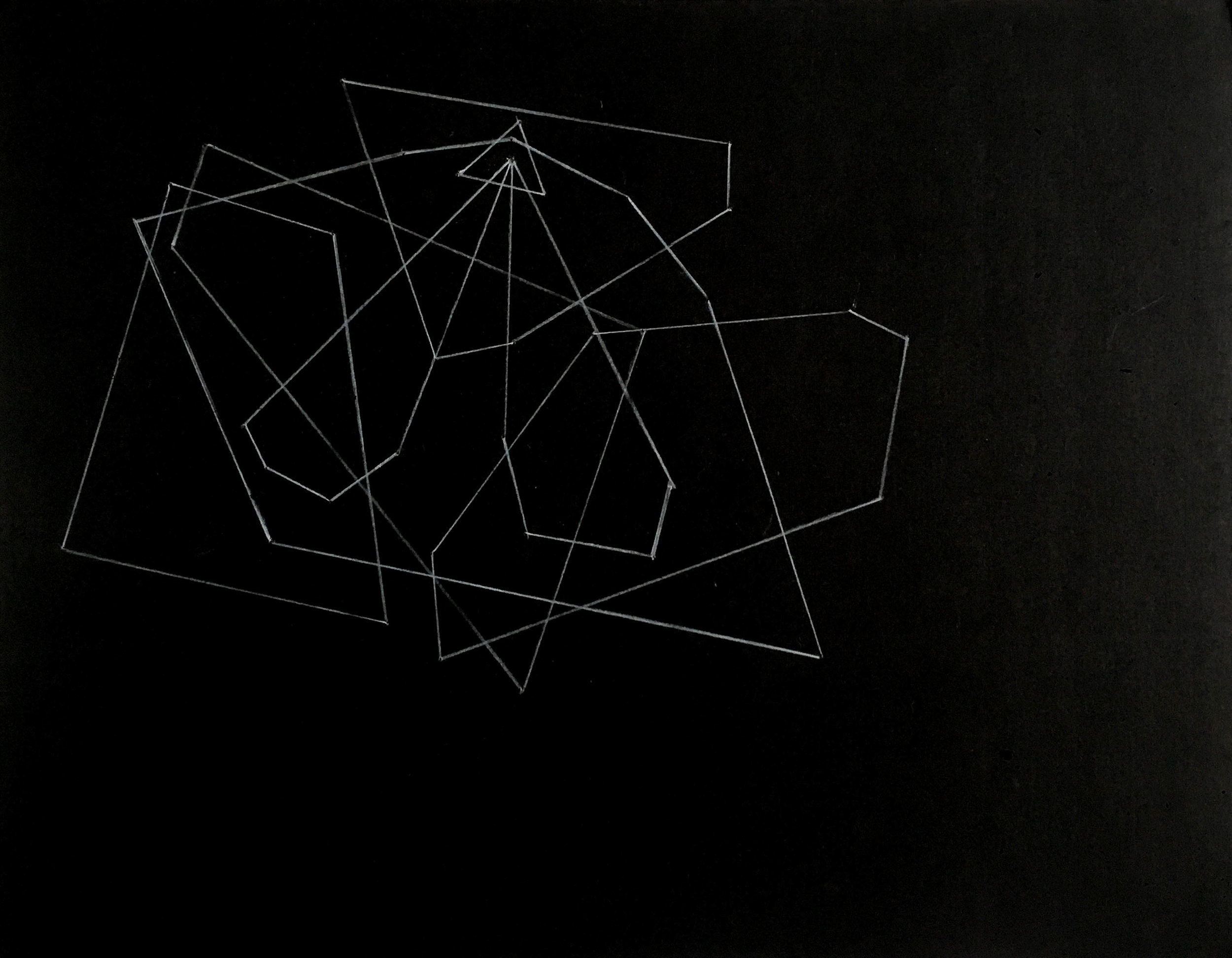

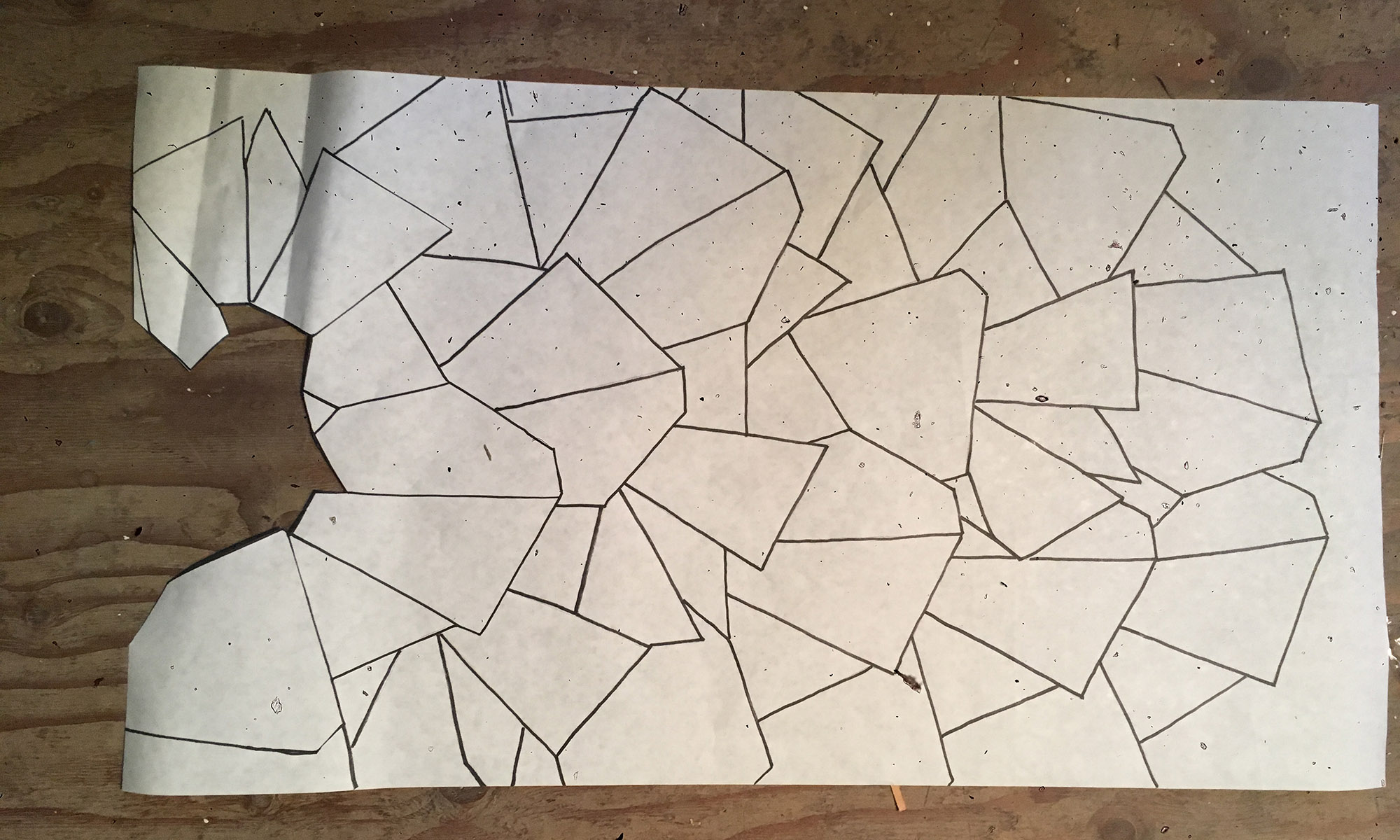

Thinking of creating a reference between a worn object and a geological feature, a skin and garment that relates to the earth and solid material I used the facets of a found rock to create the cloak from.

The rock and its models.

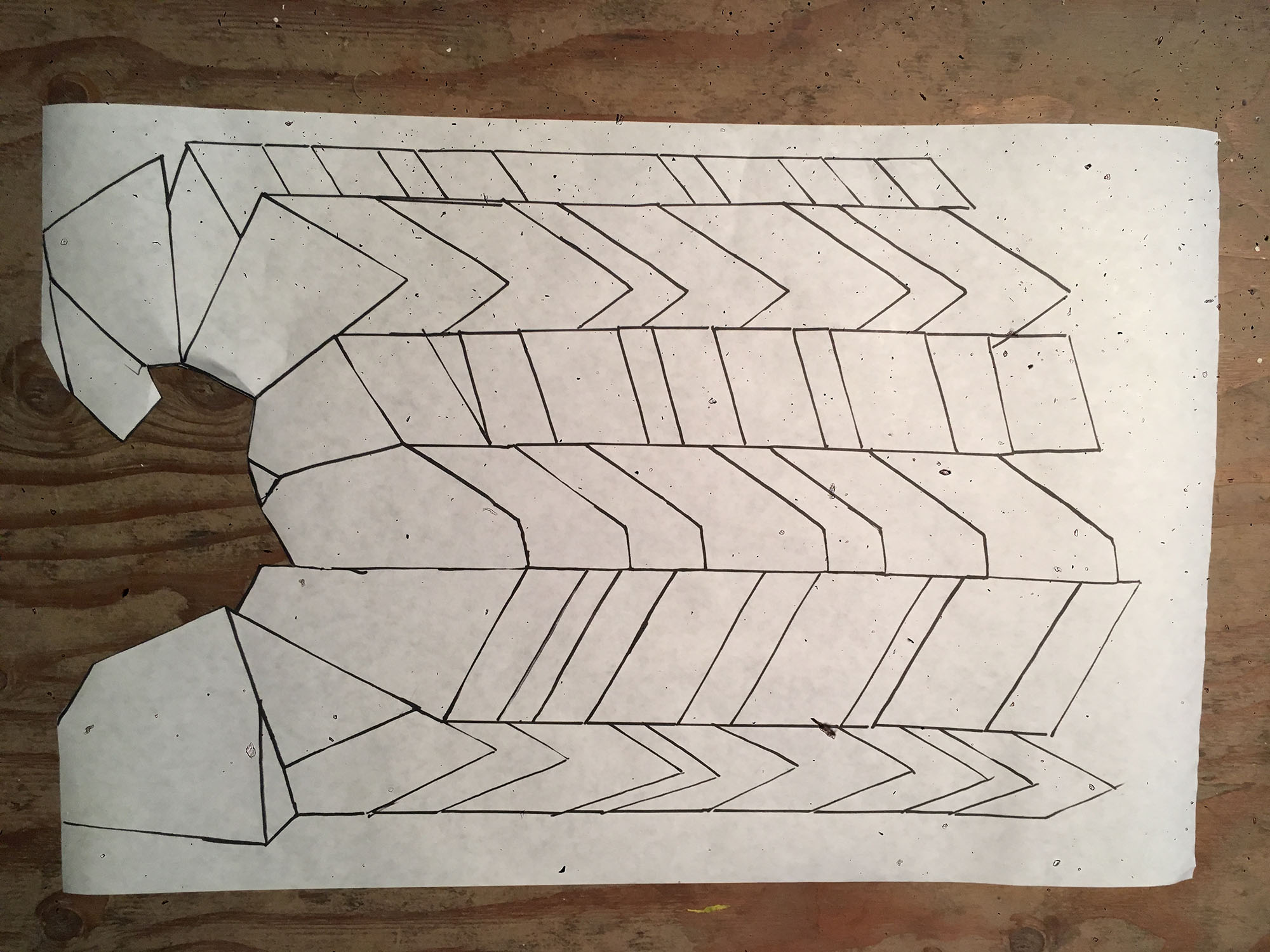

The facets of the found rock served as the layout for each part of the chrysalis cloak.

Drawings of each face of the rock. Studies and interpretations.

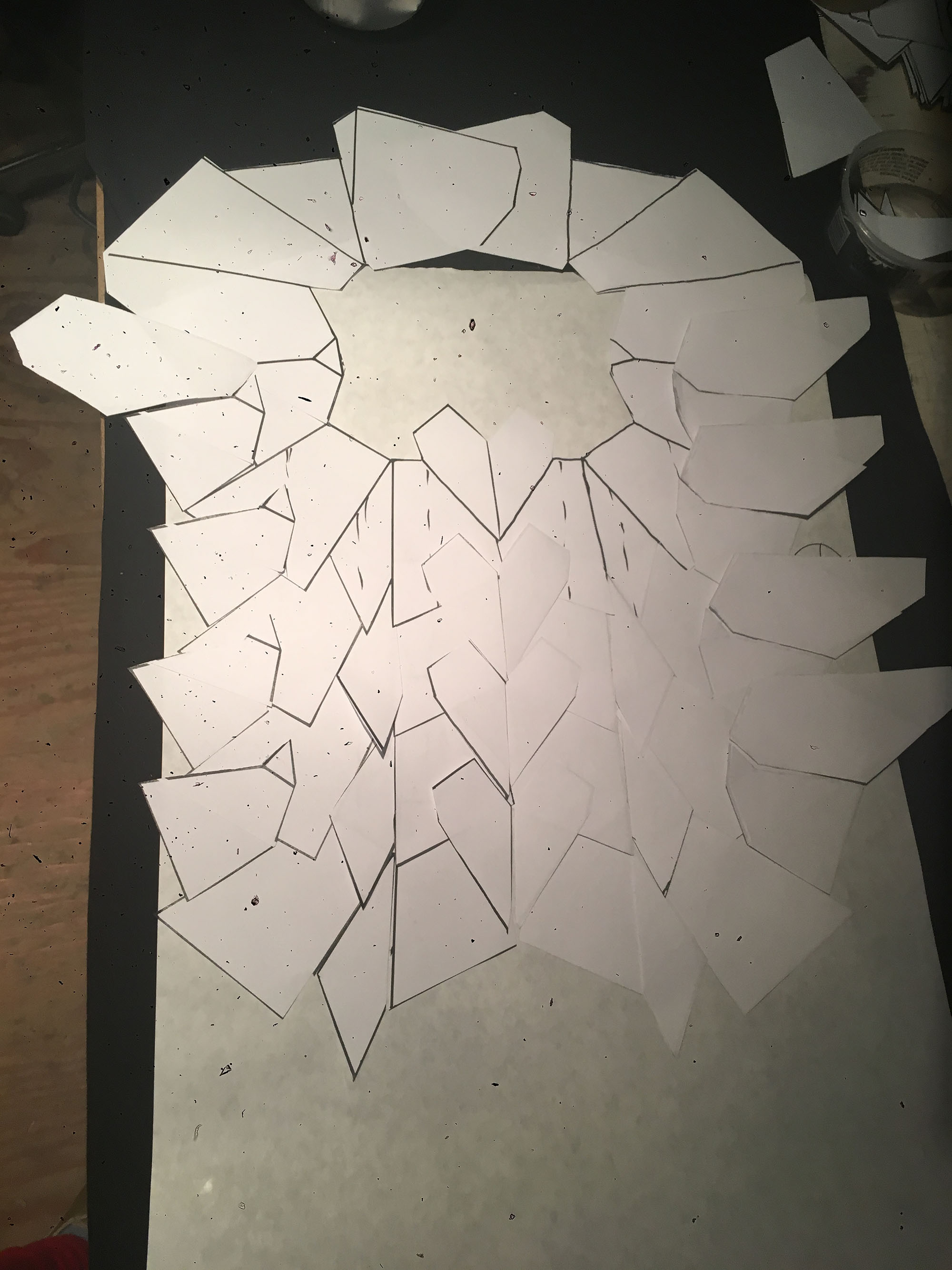

The next step, after isolating each facet of the rock, was to figure out what the layout should look like. I began with creating the collar and then add the body of the cloak pieces, while experimenting with symmetrical and asymmetrical layouts.

In the end I settled for one of the symmetrical layout, one because I would have to make a custom piece for each glass part on an asymmetrical layout and I only had a very limited amount of raw material with no possibility to get any more and secondly the look of it referred more to exoskeletons and armor.

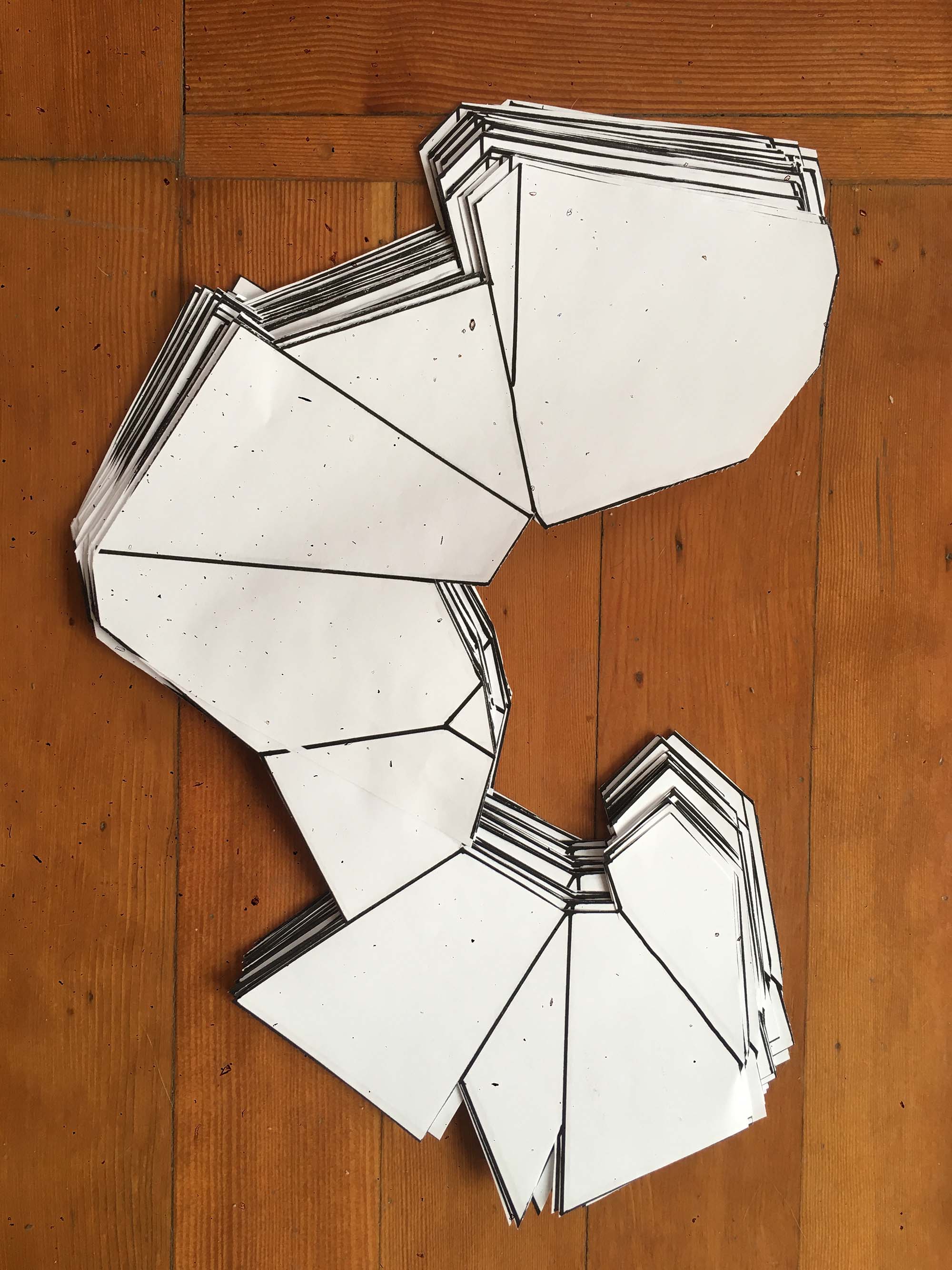

I then began to create a styrofoam dummy as well as cutting all the cloak parts. At this point I had boxes full of ceramed, cut in half lollipop Rhino pieces. I laid out the number of pieces I needed of each facet and cut with a diamond saw each part out of the lollipop shapes. Each part then got beveled and drilled for stitching it together.

The cloak contains over 170 individual Rhino glass part. The unique properties of the Rhino glass material make it extremely shatter and impact resistant, which is why it can be worn and used at all. The scales of the cloak when moved emit an unique sound ranging from bells to rattle.

After the cloak was done my collaboration with Alethea Alexander and Alexandra Bradshaw Jerby began. They are both professional dancers. Alethea is currently Assistant Professor at the University of Washington School of Dance and Alexandra is a Predoctoral Lecturer and M.F.A in Dance Candidate at the University of Washington.

Alexandras website:

Alethea website:

Through their embodiment the object first began to develop a voice and character Together we practiced and selected movements to create a composition that was both improvisation and choreographed movement. We recorded the performance in addition to live performances that are held in connection with the Bellevue Arts Museum Biennial at the Bellevue Arts Museum. Performances are scheduled for every first Friday Artwalk for the duration of the exhibition.

You can find more information here:

I am proud and honored to have received the JOHN & JOYCE PRICE AWARD OF EXCELLENCE . The price consists of a solo exhibition at BAM ( in 2020) and a $5,000 cash prize.

Here is a video of the full performance which ranges from 15-20 minutes.

.